Introduction to Building Information Modeling (BIM)

Building Information Modeling (BIM) stands as a cornerstone in the modern construction and design landscape, revolutionizing design, project management and execution. Working alongside leading engineers, architects, and building designers at The WEBBER/SMITH Group®, I’ve observed the transformative impact of BIM, especially in early design phases, clash prevention, and project management.

Understanding BIM and Its Capabilities

What is BIM?

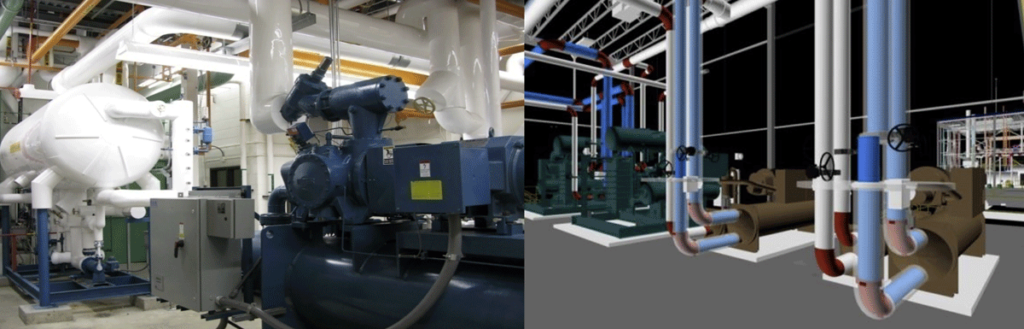

BIM represents a process supported by technology for creating digital representations of physical and functional characteristics of places. It transcends traditional drafting or 3D modeling, encompassing everything from building geometry to spatial relationships and component properties.

The Multidimensional Advantages of BIM

BIM’s approach is not confined to creating complex 3D models. It’s a comprehensive process that allows for analysis and manipulation to forecast outcomes, providing a predictive capability that is invaluable in construction.

BIM in Action: Clash Prevention

Anticipating and Resolving Conflicts

BIM’s ability to preemptively identify and resolve design conflicts is one of its most lauded benefits. John Kirk, BIM Manager at The WEBBER/SMITH Group®, states, “With BIM, we can identify and solve potential issues before they become real-world problems, throughout the design process, ensuring a smoother design and construction process and delivering cost and time savings to our clients.”

Case Studies: BIM for Clash Detection

Our involvement in complex projects where multiple systems intersect in confined spaces has demonstrated BIM’s prowess in detecting and resolving clashes, often between structural elements and MEP systems, well before construction begins.

BIM and Project Management: A Symbiotic Relationship

Streamlining Workflow and Communication

BIM is the nexus for collaboration, bringing together all project stakeholders on a unified platform. This synergy is essential for effective decision-making and maintaining project momentum.

Real-Time Updates and Accessibility

BIM allows for immediate project updates and accessibility, a feature that has become indispensable for contemporary project management and enables seamless remote collaboration.

The Tangible Benefits of BIM for The WEBBER/SMITH Group®

Enhanced Accuracy and Reduced Rework, focus on design

The integration of BIM into our processes has markedly improved accuracy and reduced the need for rework, ensuring that projects are executed correctly from the outset, and allows our design team to focus on the design

Improved Resource Management

The detailed modeling capability of BIM facilitates optimal resource allocation, enhancing project cost-effectiveness and reducing waste, in line with our sustainable engineering ethos.

BIM: A Testament to Our Commitment to Innovation

Staying Ahead with BIM

At The WEBBER/SMITH Group®, our adoption of BIM reflects our dedication to leading-edge technology, enabling us to deliver projects with unmatched precision.

The Future of Construction with BIM

BIM’s influence in the construction sector is poised to expand, continuing to distinguish firms that prioritize quality, efficiency, and collaboration.

WEBBER/SMITH is Embracing BIM for Seamless Service and Improved Productivity

The advantages of BIM in clash prevention, early design decisions, and project management are clear and significant. John Kirk, BIM Manager, encapsulates our perspective: “BIM is not merely a tool; it’s a comprehensive process that guarantees our projects are built correctly the first time.” At The WEBBER/SMITH Group®, we are not just constructing food-safe environments; we are pioneering industry benchmarks for efficiency and innovation. BIM is integral to our operations, ensuring that we consistently deliver superior service to our clients.